multi disc screw press

a new age solid liquid separation

ABOUT

Multi Disc Screw Press

Originally developed by in Japan, the technology evolved into the mainstream since the first decade of 2000. The Multi Disc Screw Press is a sludge dewatering equipment which work on the filtration mechanism after coagulation-flocculation of sludge.

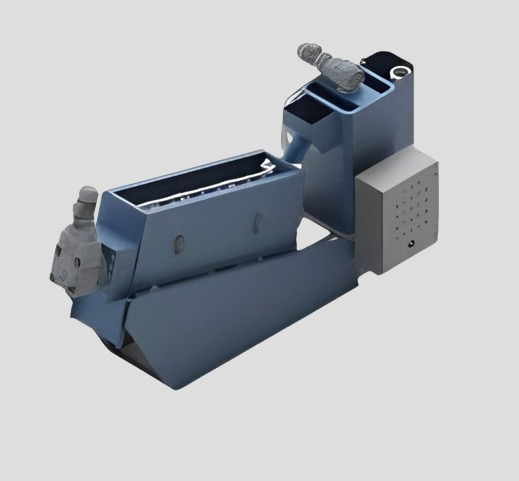

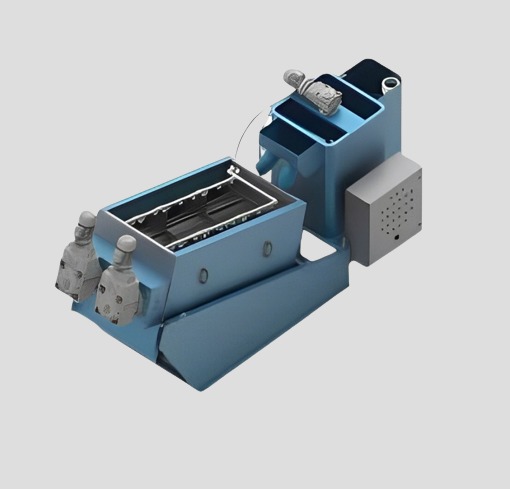

The screw press is built with a stack of alternating moving and fixed discs with varying diameter depending on the capacity. Sludge enters on feed side and moves forward using a helical screw and exits from the other side in form of cake.

The primary feature of the multi discs screw press is the stack of alternating moving and fixed discs which ensures self-cleaning as the moving discs are displaced by the screw profile in a reciprocating circular profile

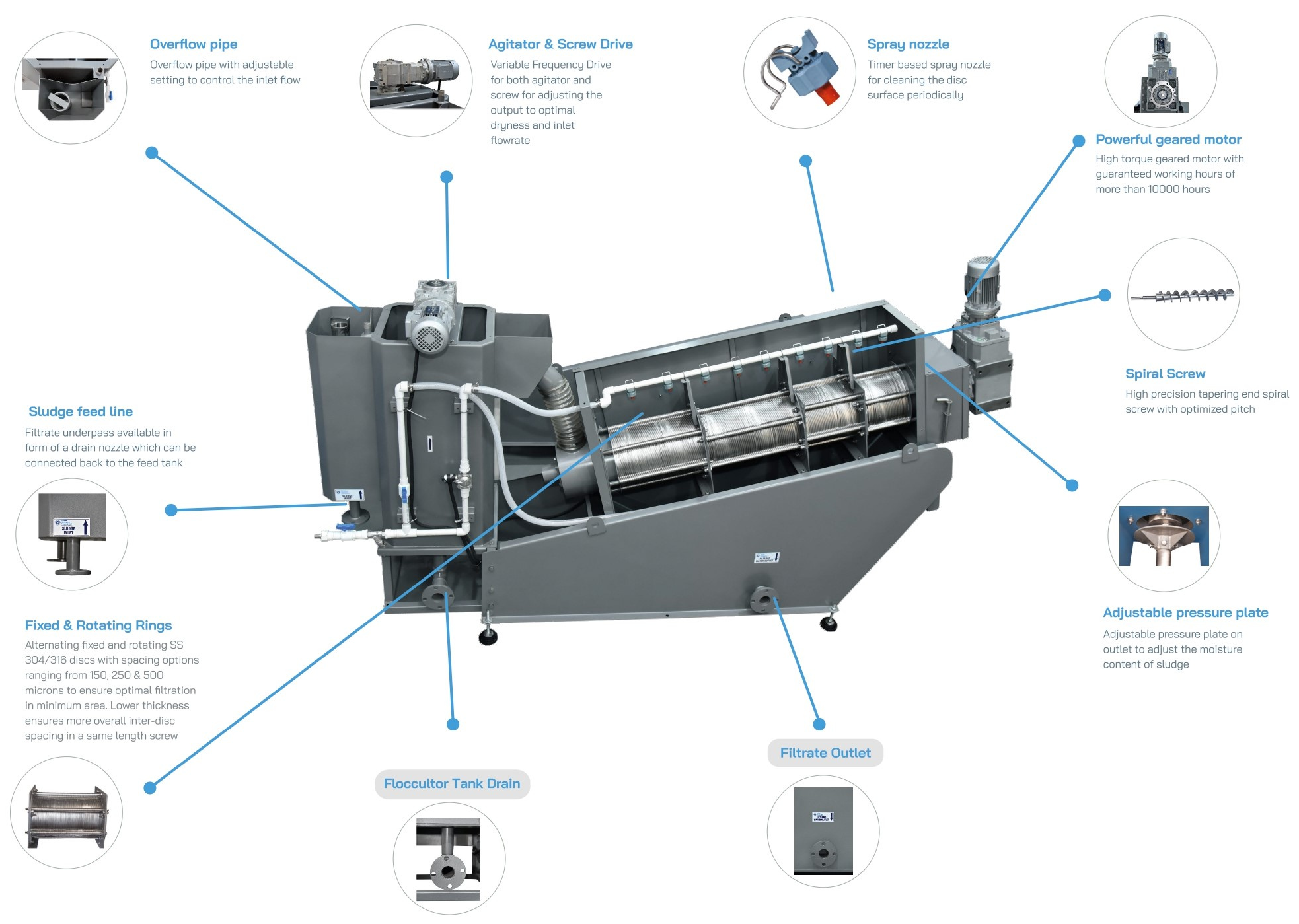

The major components of a multi discs screw press are as follows:

a. Sludge Feed Line _ from where the sludge is feed

b. Overflow weir pipe for return of excess overflow

c. Flocculator agitator drive for enhancing coagulation and flocculation

d. Spiral Screw powered by a gearbox and Alternating Discs/Rings, the heart of the system

e. Spray nozzle for cleaning of sludge leakages outside the discs

f. Adjustable pressure plate to control the sludge dryness

g. Filtrate outlet for returning the filtrate to plant

h. Flocculator tank drain for draining out flocculator tank

The major components of a multi discs screw press are as follows

Working principle

Typically, there are 4 stages of sludge dewatering in a multi disc screw press

More DetailsHow does a Multi Disc Screw Press work?

Stage - 01

In the first stage of flocculation

- The sludge enters the inlet nozzle provided below the inlet chamber by a sludge feed pump. There is a adjustable weir coupler for controlling the feed flow and returning the excess flow to the feed tank

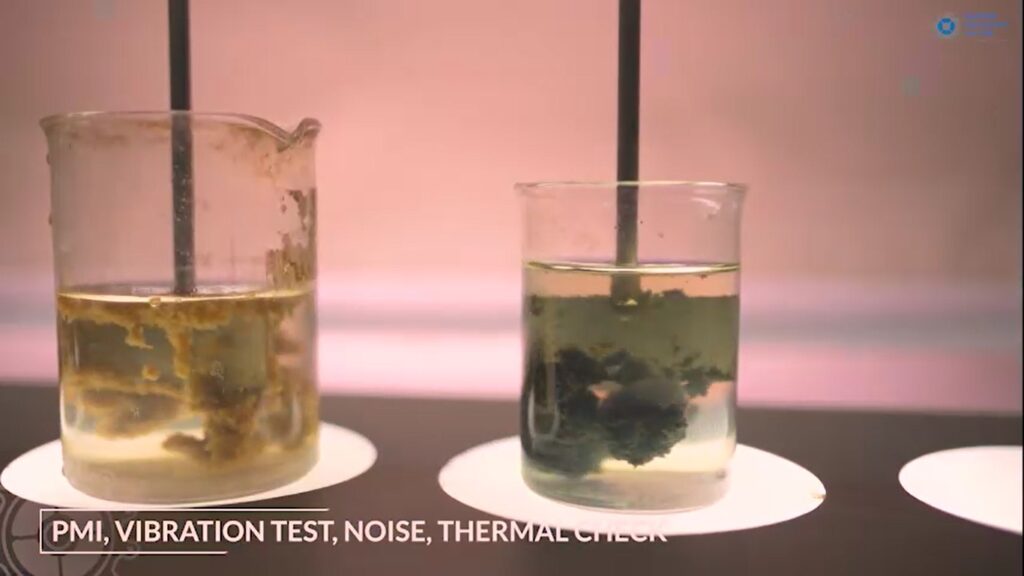

- Sludge flows through a triangular weir and baffle where based on the sludge characteristics anionic or cationic polyelectrolyte is dosed

- Then, the sludge gets coagulated and flocculation is enhanced in the flocculator tank equipped with a VFD controlled slow moving mixer ranging from 12-22 RPM. This stage is crucial for the sludge floc to mature and get bigger in size

- The coagulated sludge subsequently enters the first screw chamber trough the flexible hose

Stage - 02 & 03

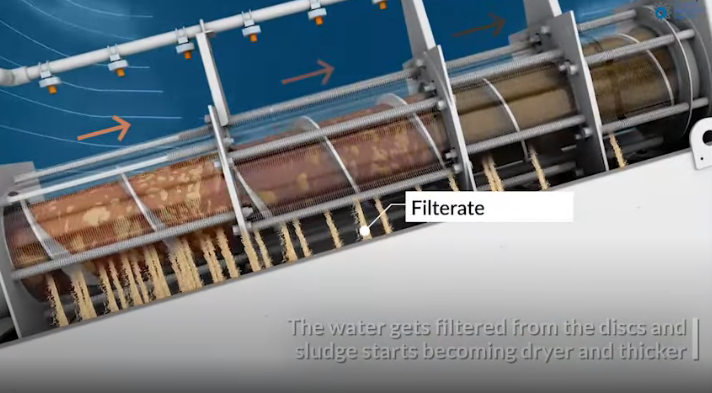

In the second & third stage of thickening and dewatering

- As soon as, the coagulated sludge enters the first screw chamber, the water gets filtered from the discs and sludge starts becoming dryer and thicker as it moves forward by the helical screw inside the chamber

- The last compartment opens against an adjustable pressure plate

- This pressure plate can be adjusted based on the dryness of sludge cake required to 2 adjustments of 3 mm and 5 mm using gauge strips provided with the machine

Stage - 04

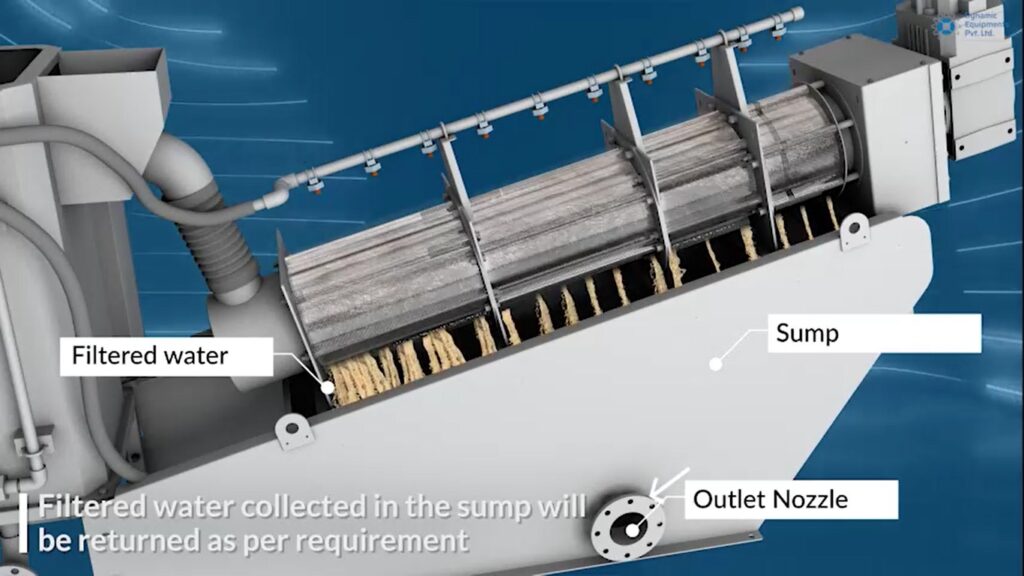

In the fourth stage of filtrate recycle

- The filtered water which is collected in the sump with returned to the feed tank or the effluent treatment plant for further processing or as per application

- DEPL’s multidisc screw press is also equipped with a self-cleaning water jet arrangement to clean the disc surface in case of any sludge leakages outside the discs, this arrangement can either be manual or automatic controlled by the solenoid valves shown here via a PCB based control panel

- The self cleaning mechanism ensures clogging free reliable and consistent operation

Comparison with other dewatering equipment

Dynamic Equipment’s Multi Disc Screw Press differentiates from cotemporary dewatering equipment like centrifuges or filter press by following features:

6-10 times lower power consumption

5 year maintenance free operation proven in field

Low speed of < 4-6RPM ensure negligible wear and tear

Lower polyelectrolyte consumption

Multi Disc Screw Press vs Centrifuge vs Filter Press

A typical case of 10 cum/hr feed flow @ 1% solids w/w

| Parameter | Multi Disc Screw Press | Centrifuge Decanter | PP Filter Press |

|---|---|---|---|

| Power Consumption | 1KW | 20kW | 5kW |

| Maintenance Mechanical | Operated at only 4 RPM with almost zero wear & tear Complete built is in SS 304/316 | Operated at only 4000 RPM with high chances of major wear & tear : Only water contact parts are in SS and rest is in MSEP | Replacement of cloth due to clogging. Build is generally MSEP thus high corrosion potential |

| Solid Content of Sludge Dewatered | 20-25% w/w (75-80% moisture) | 18-20 %w/w (80-82% moisture) | 20-25% w/w (75-80% moisture) |

| CAPEX | 10% higher than owning a centrifuge or filter press | Highest cost in the category | Lowest cost |

| Recurring CAPEX | Almost zero | Very High due to vibrations and bearing replacement | Medium mostly requires replacement of filter cloth |

| Chemical Cost | 50% of that from centrifuge when processing biological sludge | Highest requirement of polyelectrolyte | Almost same as the Screw Press |

| Noise & Vibrations | No noise and vibrations as all moving parts are at low RPM | Very high noise level | No Noise as no moving parts except the feed pump |

| Labor Cost | No labor cost of manual handling of sludge as it is in continuous application | No labor cost of manual handling of sludge as it is in continuous application | Very high labor intensive due to cleaning of cloth and changing the cloth |

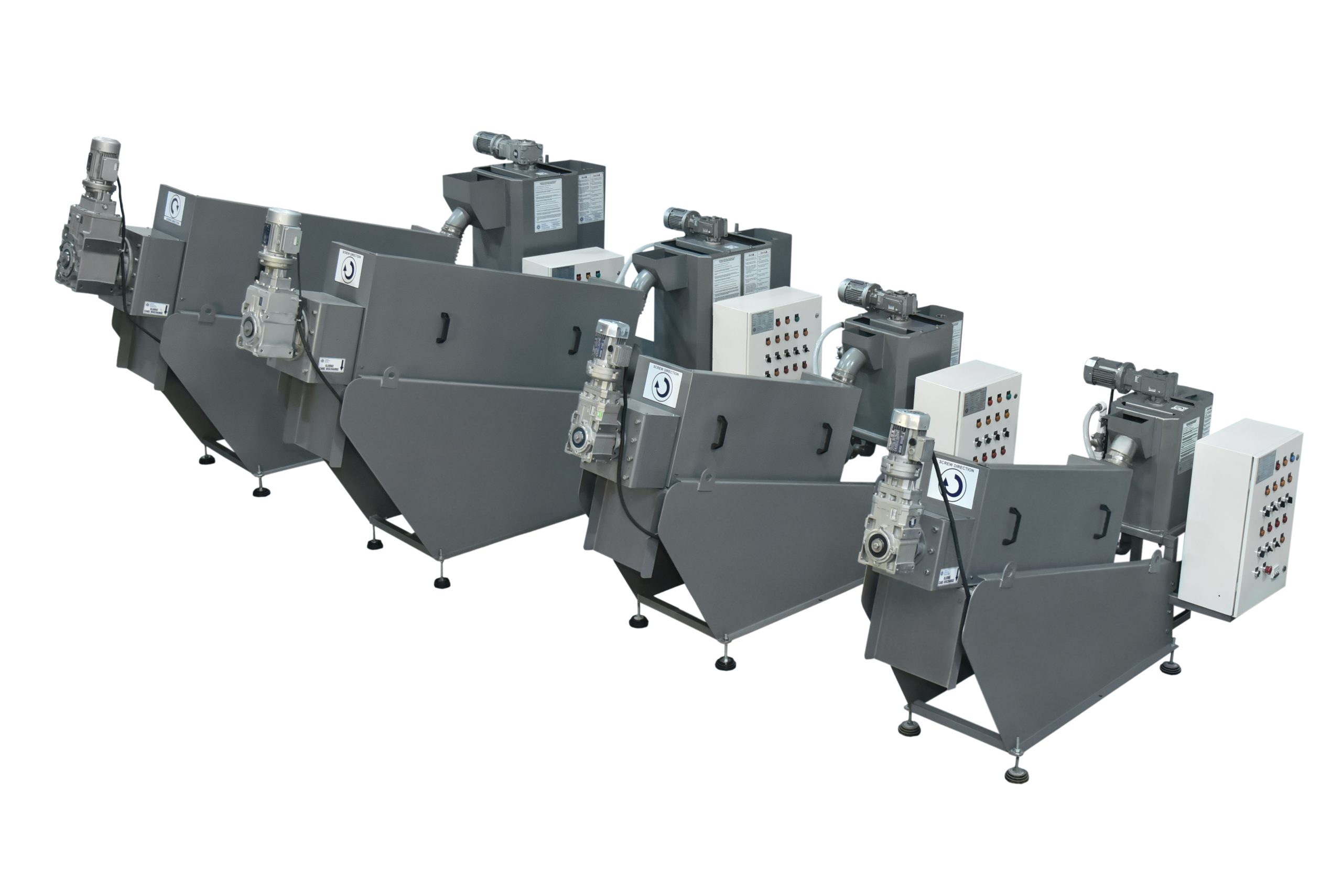

Configurations Available

The screw press is a modular design which can be provided in 1, 2, 3 and up to 4 screw in single machine as shows here for illustrations.